- Process gas available

- Vacuum

- Powder processing

- With high frequency generator

- Painting / Plating

- Adhesion / Bonding

- Dispersion / Cohesion improvement

- Cultivation / Dental Care

- Cleaning / Sterilization

- Etching

- Thin film formation

- Hydrophobic

- Lipophobic / Stain repellency (under development)

- Lipophilic (under development)

- For experimental use

- For manufacturing

- Processing to special shapes (film, powder, tube, three-dimensional objects, etc.)

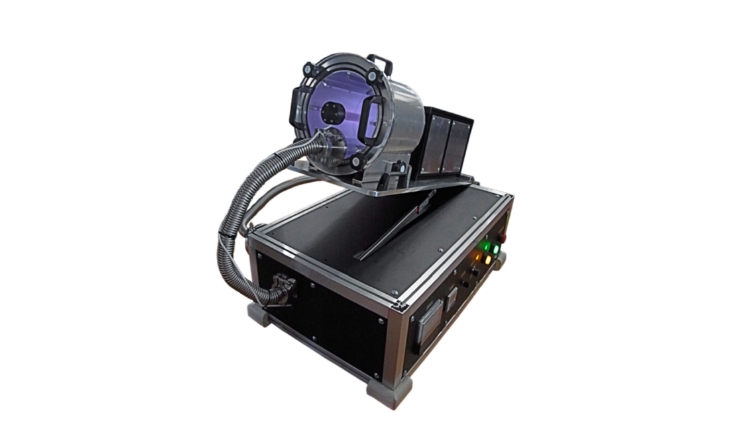

Rotary Benchtop Vacuum Plasma System YHS-DφS

Product Overview

High treatment effect for surface modification, cleaning, and hydrophilic treatment

Rotating chamber for batch processing of front and back

Powder surface treatment is possible in a dry environment

Cylindrical electrodes that can be rotated in the chamber

Discharge by applying a high frequency to the central electrode opposite the tubular electrode

The processing workpiece rolls in the rotating chamber and can be processed at once.

Cleaning of resin molded products, cleaning of MEMS pretreatment of adhesive molded products, powder surface treatment in dry environments, etc.

Etching, thin film formation, water repellency, redox of powders and small parts

Specification

Device name: Rotary benchtop vacuum plasma device

Model YHS-DφS

External dimensions 820mm(W)×600mm(D)×680mm(H)

Weight 100kg

Rotating part φ210×200mm(D)

Output adjustment

1 gas system (2 or more systems are optional)

Gas control method Needle valve (mass flow controller optional)

Pressure adjustment

Power supply 100V, 30A (50Hz/60Hz)