Hydrogen-free reduction of oxidized metal parts Direct vaporization type reduction device “DH-Reduction” released on January 20

Sakigake Semiconductor Co., Ltd. (Shimogyo-ku, Kyoto-shi, Kyoto, Representative Director: Koji Taguchi), which develops and sells plasma equipment, has developed a new technology for reducing the surface of metal products such as naturally oxidized printed circuit boards and lead frames with plasma without using hydrogen, and will release a dedicated plasma device “Direct Vaporization Reduction Device DH-Reduction” on January 20, 2023. Since it is safer, less cost-effective than the conventional hydrogen plasma reduction method, and can be processed in a shorter time, it will be sold to a wide range of applications such as industrial products using silver and copper, medical products, and daily necessities.

■Safe, low-cost, hydrogen-free plasma reduction method

Silver and copper oxidize naturally and have the property of being covered with an oxide film on the surface. Components such as substrates and lead frames used in industrial products are currently removed using chemicals and reducing agents or by hydrogen plasma treatment to improve electrical conductivity and bondability. These reduction methods are not simple, such as the metal surface is easily deformed, the process has a high environmental impact, and the work is dangerous. The reduction method newly developed by Sakigake Semiconductor is a new plasma technology that uses polyols of divalent or higher. Unlike conventional hydrogen plasma treatment, hydrogen-free and large-scale explosion-proof equipment is not required. It is safe, space-saving, low-cost, and can be reduced in a short time. (Patent pending)

Photo: Reduced 10-yen coin (left) oxidized by DH-Reduction (right)

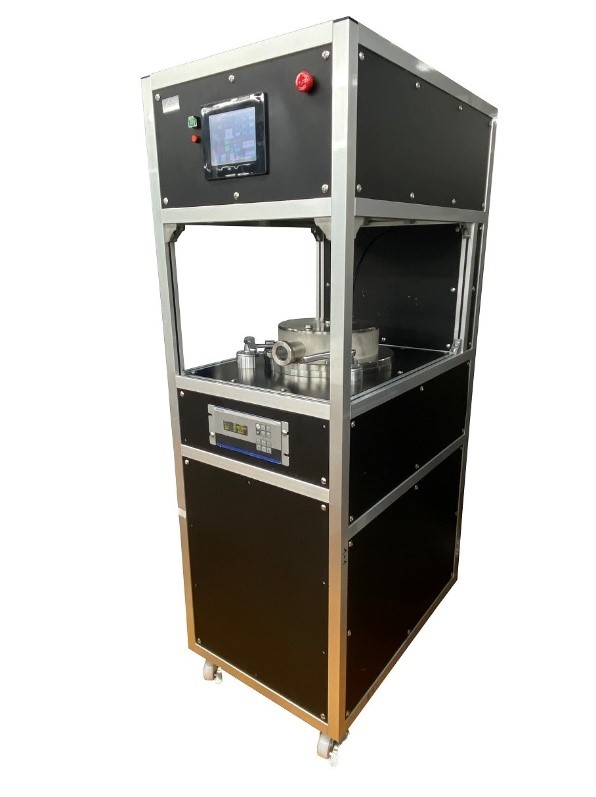

Photo: DH-Reduction device

■Safe and improved production efficiency

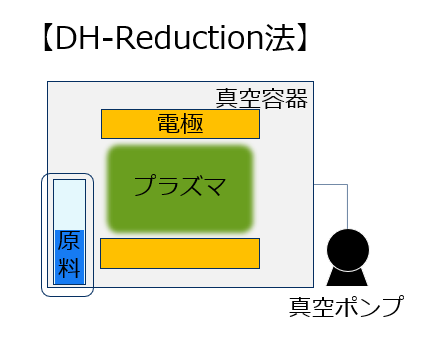

The “Direct Vaporization Type-Reduction Device DH-Reduction” does not use externally connected gas but performs treatment by placing raw materials directly in the chamber as shown in the figure below.

Since it is a dry treatment, there is no need for waste liquid treatment like the wet type. In addition, compared to conventional reduction treatment using dry hydrogen, explosion-resistant equipment and high-moon treatment equipment are not required.As a result, the initial and running costs are greatly reduced compared to conventional methods, leading to improved production efficiency.

A detailed evaluation of the reduction by this technology will be presented at the 70th Annual Meeting of the Japan Society of Applied Physics to be held in March this year.

■Product Overview

[Device name] Direct vaporization type reduction device “DH-Reduction”

[Release date] January 20, 2023

Price: 9.4 million yen (excluding tax)

| Model | Direct vaporization type – reduction device “DH-Reduction” |

| Processing vessel | Stainless steel, aluminum alloy, glass, PTFE |

| Discharge method | AC parallel flat plate type |

| Electrode stage | Stainless steel, diameter 400 mm (can be changed as an option) |

| High voltage power supply | supply High frequency (13.56MHz) |

| Output adjustment | Manual adjustment | Gas introduction | Not required |

| Exhaust flow adjustment | None (optional addition possible) | Vacuum gauge | None (optional addition possible) |

| Timer | Set plasma irradiation time between 0 and 9999 seconds |

| External dimensions | W: 560mm × D: 560mm × H: 400mm (excluding protrusions) |

| Power supply | Single phase 200V, 50 or 60 Hz, 15A |

▶Click here to contact us.