We Have Developed The “Flip-Flop Coater FFC-400M”, A Vacuum Plasma Device That Marks The Industry’s First Practical Application Of Achieving Repeated Water-Repellent And Hydrophilic Effects In A Dry Process.

The new factory will serve as a pillar of our new business initiatives.

SAKIGAKE Semiconductor Co., Ltd., located in Shimogyo-ku, Kyoto City, Kyoto Prefecture, and led by CEO Mitsuji Taguchi, is a developer and seller of plasma equipment. The company has developed the “Flip-Flop Coater FFC-400M”, a vacuum plasma device that marks the industry’s first practical application of a dry process plasma treatment. This technology creates a thin film that is water- repellent in air and hydrophilic in water. The film formation technology has high stain-proofing and waterproofing effects and is expected to extend the life of flexible semiconductor devices. The results of this research were announced at the Japan Society of Applied Physics on March 25th, and a patent application has been filed for the equipment and the thin film it creates. The equipment will be used for new business purposes at the company’s new factory, which is scheduled for completion next year, and test marketing will begin this month.

■ This Technology Effectively Repels Dirt, Allowing It To Be Easily Washed Away With Just Water

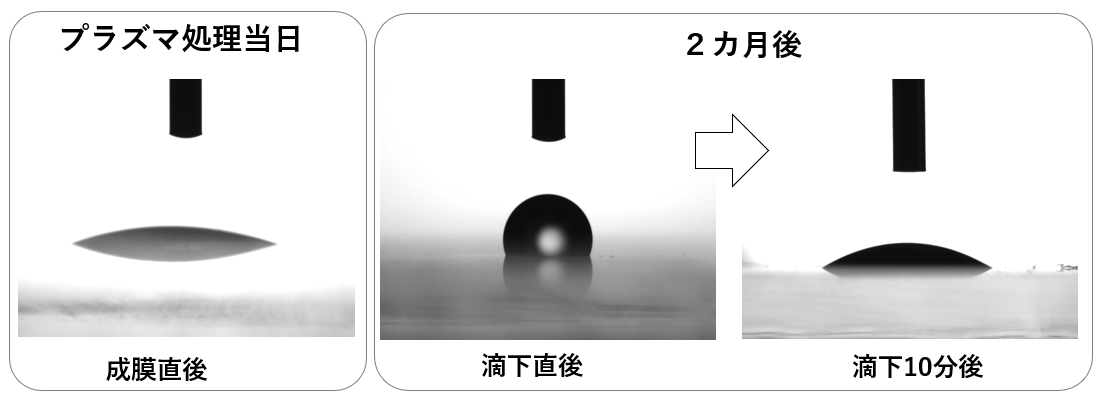

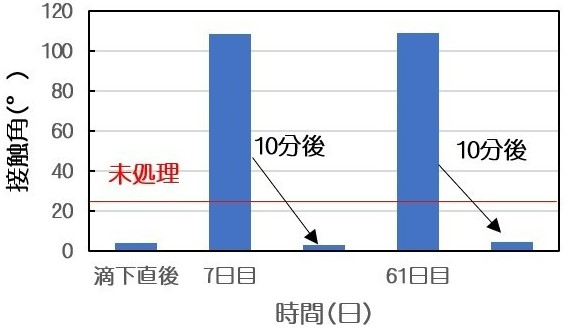

SAKIGAKE Semiconductor Co., Ltd. has developed a unique film deposition technology that leverages the “flip-flop phenomenon,” where a material is water-repellent in air but hydrophilic in water. While there are existing film-forming technologies that achieve the same effect in wet processes, we are the first in the industry to succeed in dry processes such as plasma technology. Our research has led to the development of the “Flip-Flop Coater FFC-400M,” a dedicated plasma device that alternates between creating water-repellent and hydrophilic films under specific conditions. Objects treated with this device exhibit high anti-fouling, waterproof, and oil-resistant effects, and even dried dirt can be removed with just water. This technology is expected to find wide-ranging applications, including touch panels, lenses, outdoor components, and textiles. Unlike wet processes, where the coating agent tends to be embedded in uneven areas resulting in uneven film thickness, our plasma treatment allows for the formation of a uniform film thickness. This not only reduces environmental impact and management costs but also extends the life of films such as those used in flexible displays, thereby accelerating the practical use of organic devices.

<Change in contact angle of glass after plasma treatment by flip-flop coater>

■ We Are Planning To Initiate Contract Business At Our New Factory

SAKIGAKE Semiconductor Co., Ltd. is planning to open a new facility in Kyoto City in 2023. This facility will house various plasma devices, including vacuum and atmospheric pressure devices, monitoring sensors, and other measurement instruments in a clean room environment. A key feature of this new facility will be the “Flip-Flop Coater FFC-400M”, a newly developed device that we do not plan to sell. Instead, it will be installed in the new facility to initiate the industry’s first contract processing service for repetitive water-repellent and hydrophilic film deposition. This service is expected to become a cornerstone of our new business. Starting this month, we will conduct trials of film deposition with the Flip-Flop Coater FFC-400M across a wide range of fields and commence test marketing for the new business.

Our film deposition technology also holds potential for antimicrobial effects. We plan to explore this potential further through collaborative research with other companies. Our goal is to verify these effects and develop new applications, thereby expanding the scope and impact of our technology.

■ Equipment And Items For Contracted Processing

[Vacuum plasma system] “Flip-Flop Coater FFC-400M

[Features] High waterproofing, oil proofing, and stain-proofing effects by uniform coating

[Object size] Up to A5 size (to be expanded in the future). (To be expanded in the future)

[Target material] Polytetrafluoroethylene (PTFE) *Material exclusive for this device

[Application] Coating of touch panels, outdoor components, etc

※The vacuum plasma system “Flip-Flop Coater FFC-400M” is our dedicated equipment for contracted processing.

■ 69th Hybrid Spring Meeting Of The Japan Society Of Applied Physicshttps://meeting.jsap.or.jp/

(Dates) Tuesday, March 22 – Saturday, March 26, 2022

(Venue) Local: Aoyama Gakuin University Sagamihara Campus, Online: Zoom

SAKIGAKE Semiconductor (Presentation) March 25, 15:45- (Lecture No. 25P-E104-11)

▶ Click here for PDF documents

▶Click here to contact us.