We Have Developed An Industry-First Special Plasma Processing Technology That Activates PTFE Powder Dispersed In Liquid. This Innovative Approach Has Led To The Development Of New Materials For Applications Such As Paints And 3D Printers.

SAKIGAKE Semiconductor Co., Ltd., located in Shimogyo-ku, Kyoto City, Kyoto Prefecture, and led by CEO Mitsuji Taguchi, is a developer and seller of plasma equipment. The company has pioneered the industry’s first special plasma processing technology. This technology activates the surface of the fluoropolymer “PTFE” powder using our proprietary plasma technology and allows it to disperse evenly in liquids such as ethanol. While PTFE is typically challenging to disperse in liquids and resins, this innovative technology facilitates the development of new materials, including paints and materials for 3D printers. Test marketing of this special processing will commence this month, with plans to offer it as a contracted processing service in a new business launching next spring.

■ We Have Developed A Special Plasma Processing Technology That Enables Uniform Dispersion In Both Liquids And Solids

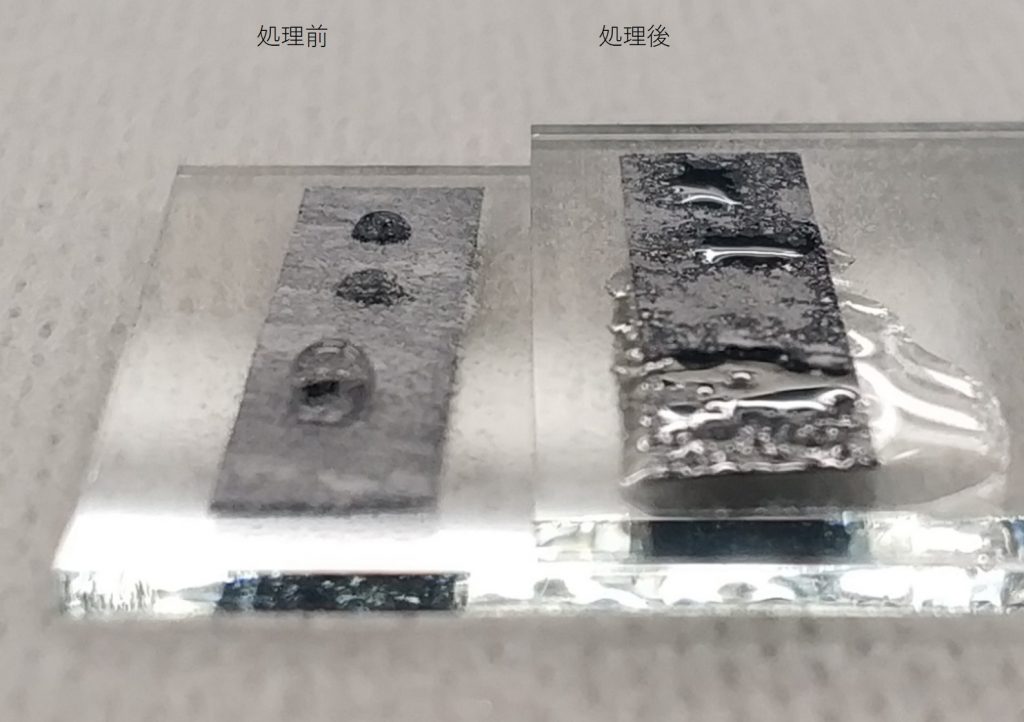

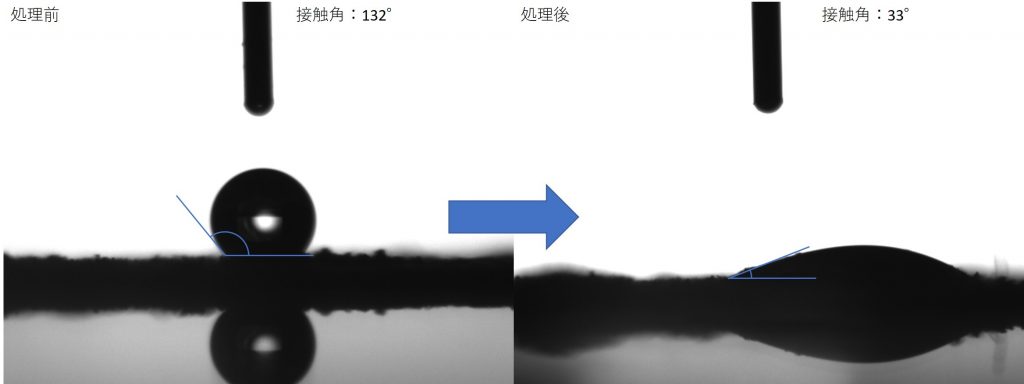

PTFE (polytetrafluoroethylene), a fluoropolymer utilized in Teflon processing, is renowned for its exceptional heat and chemical resistance, making it suitable for a wide range of applications. However, uniformly dispersing PTFE powder in liquids and resins has been a longstanding challenge due to its inherent properties. We have been conducting research and development on activating PTFE through plasma treatment and have successfully developed a unique special plasma processing technology. This technology enables the uniform dispersion of PTFE powder in organic liquids such as 1-methyl-2-pyrrolidone (NMP), ethanol, and hexane without the need for a dispersant, or in some cases, with only a minimal amount. In conjunction with this, we have also developed a new dedicated plasma device to facilitate this special plasma processing technology.

<Our Experiment: Enhancing the Wettability of PTFE Powder in Organic Solvents>

■Customized Plasma Processing Is Set To Commence At Our New Facility Starting Next Spring

Given the specialized nature of this plasma process technology, we provide it as a contracted processing service.

Starting in spring 2023, we will launch a new contract processing business at our newly constructed facility in Kyoto City. This venture will involve test marketing of our innovative technology across various industries. This technology simplifies the development of resin mixtures containing PTFE powder, which we anticipate will increase demand in diverse sectors, including automobile parts like bumpers, robotics, construction materials, and bearings. We also foresee its effectiveness in creating new materials for 3D printers, a field that has seen significant growth in recent years. Our commitment to continuous research and development, guided by test marketing insights, aims to further enhance our technology. We are particularly focused on developing a new technique for surface modification of fluoropolymer powder that can be uniformly dispersed in liquids such as 1-methyl- 2-pyrrolidone (NMP), ethanol, and hexane, and eventually, even in water.

※Dispersion : refers to the phenomenon where one of two substances that do not mix well with each other exists uniformly in the other substance in the form of fine particles.

▶ Click here for PDF documents

▶Click here for the article published in Nikkan Kogyo Shimbun *With permission for copyright use from Nikkan Kogyo Shimbun, Ltd.

▶Click here to contact us.