Pretreatment for fixation of adhesion and cell culture Newly developed polycarboxylic acid surface formation technology by vacuum plasma

(Shimogyo-ku, Kyoto-shi, Kyoto; President: Koshi Taguchi), which develops and sells plasma systems, has developed a new technology for the surface formation of polycarboxylic acid by vacuum plasma, an effective pretreatment for adhesion and cell culture fixation for various applications.

This technology will be offered as a contract processing business at our new plant (Seiin Plant) from November 27, 2023.

■ Successful commercialization of highly safe technology with vacuum plasma

In the manufacturing process of microfluidic channels, hydroxyl groups (OH groups) are often preferentially introduced on the surface of plastic substrates such as polycarbonate, for example, when they are attached together.

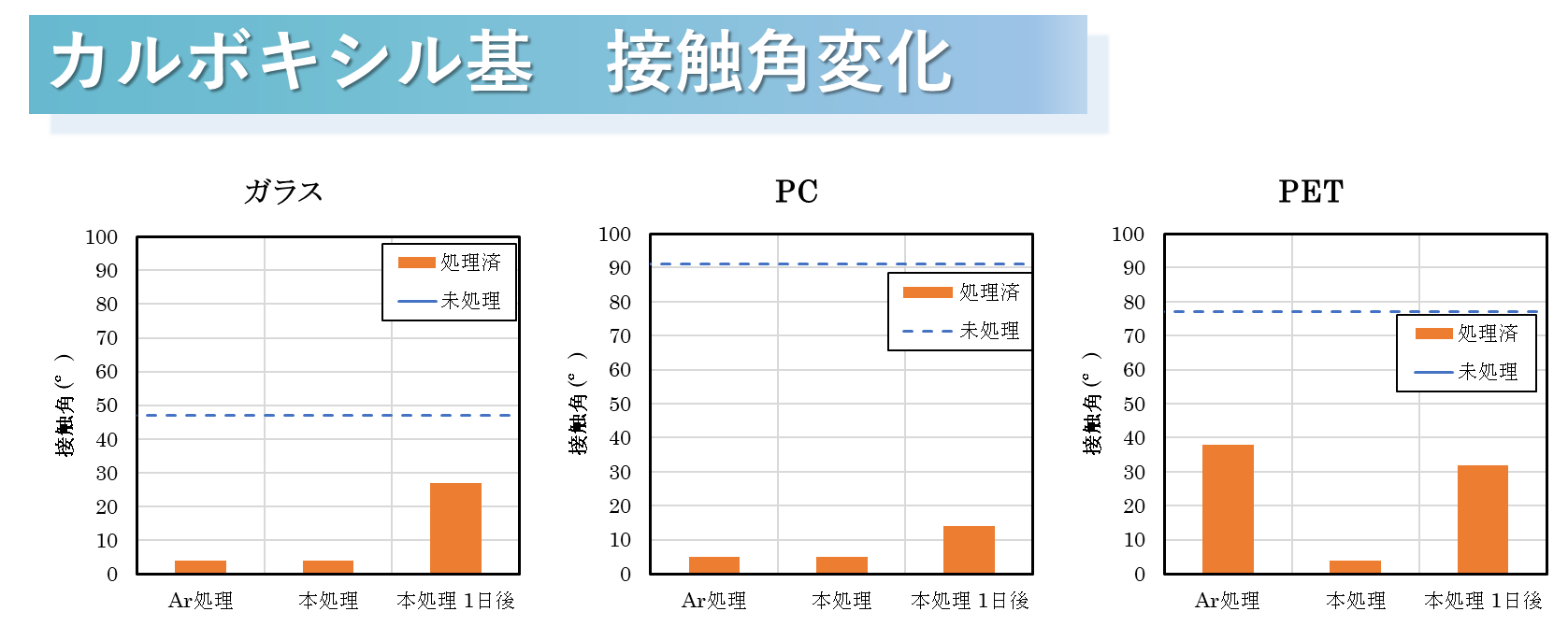

Through interviews with our customers, we have found that there is a certain market demand for the introduction of carboxy groups (-COOH) for surface treatment prior to adhesion, pretreatment of cell culture fixation, and other applications.

Conventional techniques include the use of atmospheric pressure plasma to treat acrylic acid at a certain gas-phase concentration.

Since acrylic acid is a flammable chemical, it is difficult to control temperature and oxygen concentration in this technology, and its use in the atmosphere is extremely hazardous.

In the past, there have been some cases of explosions in chemical plants in manufacturing plants and in polymerization reactions during heating.

In Kai semiconductors, based on our SAM (Self-Assembled Monolayer) formation technology, we have successfully developed and commercialized a process that is safer than atmospheric pressure plasma by using vacuum plasma technology and supplying acrylic acid in a chamber to control its condition, thereby reducing flammability. The process is safer than atmospheric plasma and has been successfully put into practical use.

■ For applications such as hydrophilization of substrates and substrates for cell culture

This technology is expected to expand to applications such as hydrophilization of substrates (another technology for long-term retention), scaffold formation for cell culture (immobilization of collagen, etc. on carboxyl groups), artificial skin with superabsorbent thin films, and base materials for divalent metal ion and enzyme sensors (medical). The material is also expected to be used as a base material for divalent metal ion and enzyme sensors (medical).

▶ Click here for PDF document

▶Click here to contact us.