Dispersion / Cohesion improvement

7 articles found.

-

- Others (checkers, transfer equipment)

- Dispersion / Cohesion improvement

- Cultivation / Dental Care

- For experimental use

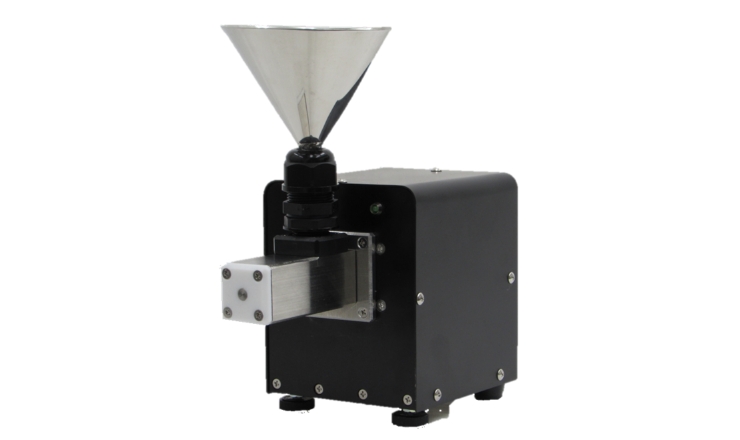

Desktop powder feeder Z03-10

Easy operation from a PC. High-precision powder feeding by stepping motor drive. Linkage with an electronic balance with communication function (optional) enables even higher precision feeding. Desktop type, compact.

Desktop powder feeder Z03-10

Easy operation from a PC. High-precision powder feeding by stepping motor drive. Linkage with an electronic balance with communication function (optional) enables even higher precision feeding. Desktop type, compact.

-

- Others (checkers, transfer equipment)

- Dispersion / Cohesion improvement

- Cultivation / Dental Care

- For experimental use

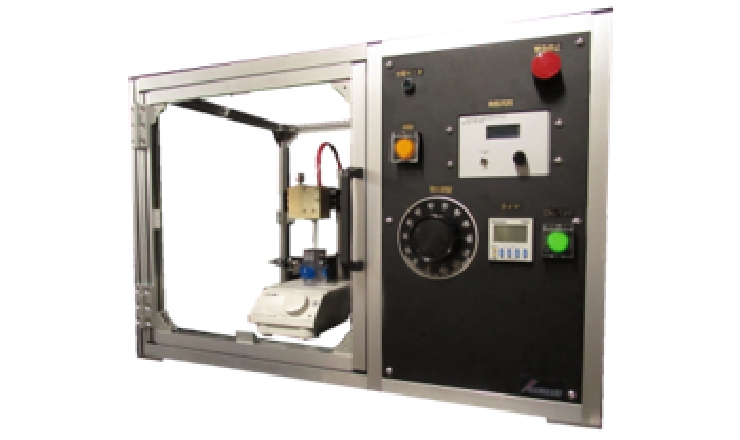

Micro Powder Feeder KDB-14A

Easy-to-use interface with touch panel control of supply volume. Continuous processing in combination with atmospheric pressure liquid surface plasma system.

Micro Powder Feeder KDB-14A

Easy-to-use interface with touch panel control of supply volume. Continuous processing in combination with atmospheric pressure liquid surface plasma system.

-

- Atmospheric pressure (direct)

- Powder processing

- Gas-less processing

- Painting / Plating

- Dispersion / Cohesion improvement

- For experimental use

- Processing to special shapes (film, powder, tube, three-dimensional objects, etc.)

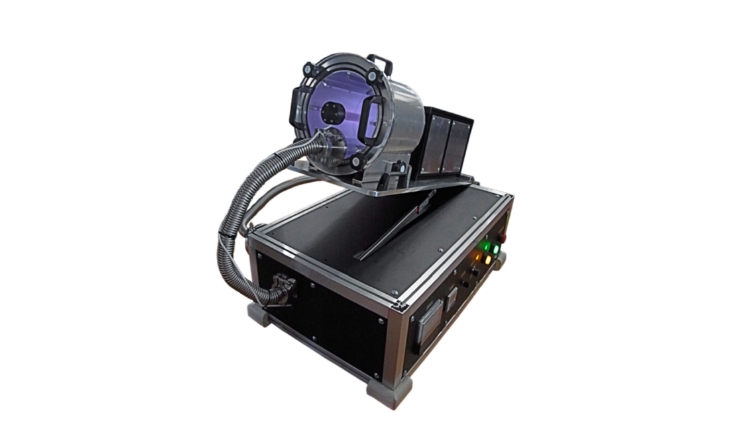

Liquid plasma system DKN-128

Improved powder dispersion by plasma in liquid. Improved production efficiency through continuous processing. Plasma treatment while breaking up agglomerations by impact group. For pre-treatment of powder plating.

Liquid plasma system DKN-128

Improved powder dispersion by plasma in liquid. Improved production efficiency through continuous processing. Plasma treatment while breaking up agglomerations by impact group. For pre-treatment of powder plating.

-

- Atmospheric pressure (direct)

- Powder processing

- Gas-less processing

- Painting / Plating

- Dispersion / Cohesion improvement

- For experimental use

- Processing to special shapes (film, powder, tube, three-dimensional objects, etc.)

Atmospheric pressure liquid surface powder plasma processing equipment PPU-800 for full-scale research

Powders do not scatter because the process is windless. Powders and liquids that were previously not mixed at all are mixed together. This promotes the cohesion of difficult-to-form materials, making them easier to process.

Atmospheric pressure liquid surface powder plasma processing equipment PPU-800 for full-scale research

Powders do not scatter because the process is windless. Powders and liquids that were previously not mixed at all are mixed together. This promotes the cohesion of difficult-to-form materials, making them easier to process.

-

- Atmospheric pressure (direct)

- Powder processing

- Gas-less processing

- Painting / Plating

- Dispersion / Cohesion improvement

- For experimental use

- Processing to special shapes (film, powder, tube, three-dimensional objects, etc.)

Atmospheric pressure liquid surface powder plasma processing equipment ASS-400

Mixed with liquid by surface treatment of powder without surfactant. Pretreatment: Pretreatment of fillers and calcined powders. Others: For development of hybrid materials.

Atmospheric pressure liquid surface powder plasma processing equipment ASS-400

Mixed with liquid by surface treatment of powder without surfactant. Pretreatment: Pretreatment of fillers and calcined powders. Others: For development of hybrid materials.

-

- Atmospheric pressure (remote)

- Powder processing

- Painting / Plating

- Adhesion / Bonding

- Dispersion / Cohesion improvement

- Cultivation / Dental Care

- Cleaning / Sterilization

- For experimental use

- For manufacturing

- Processing to special shapes (film, powder, tube, three-dimensional objects, etc.)

Large Capacity Atmospheric Powder Processing Equipment LLPP

The technology is based on the supply of gas to powder to make it flow like a liquid (fluidised bed, fluidised bed).

Large Capacity Atmospheric Powder Processing Equipment LLPP

The technology is based on the supply of gas to powder to make it flow like a liquid (fluidised bed, fluidised bed).

-

- Process gas available

- Vacuum

- Powder processing

- With high frequency generator

- Painting / Plating

- Adhesion / Bonding

- Dispersion / Cohesion improvement

- Cultivation / Dental Care

- Cleaning / Sterilization

- Etching

- Thin film formation

- Hydrophobic

- Lipophobic / Stain repellency (under development)

- Lipophilic (under development)

- For experimental use

- For manufacturing

- Processing to special shapes (film, powder, tube, three-dimensional objects, etc.)

Rotary Benchtop Vacuum Plasma System YHS-DφS

Ideal for processing powders and chip capacitors! We have added a rotation mechanism to the vacuum plasma so that the entire surface can be processed at once!

Rotary Benchtop Vacuum Plasma System YHS-DφS

Ideal for processing powders and chip capacitors! We have added a rotation mechanism to the vacuum plasma so that the entire surface can be processed at once!

Search by Category

Search by Application

- Hydrophobic / Lipophilic (under development)

- Hydrophobic / Lipophobic (under development)

- Painting / Plating

- Adhesion / Bonding

- Dispersion / Cohesion improvement

- Cultivation / Dental Care

- Cleaning / Sterilization

- Etching

- Thin film formation

- Hydrophobic

- Plasma durability test

- Lipophobic / Stain repellency (under development)

- Lipophilic (under development)

- For experimental use

- For manufacturing

- Processing to special shapes (film, powder, tube, three-dimensional objects, etc.)